Blog

Design Information

Medical textile is an area that requires high care and professionalism, and it is mainly used in institutions where human health is a priority. These products are divided into two categories:

Single-use textile products

Reusable textile products

In recent years, single-use textile products with special properties (liquid impermeability, antibacterial, flame retardancy) have been produced. The advantages of these products include not requiring washing or ironing, being recyclable, and providing an environmentally friendly use.

No washing

No detergent

No water

Recyclable material

Moreover, you can find the classic textile feel in single-use products.

Nonwoven fabrics are textile materials produced without the traditional weaving or knitting process. Instead, they are manufactured by bonding, felting, or adhesion of fibers together. Nonwoven fabrics can be created by mechanically, chemically, or thermally bonding fibers.

Here are some characteristics of nonwoven fabrics:

1. Flexibility: Nonwoven fabrics are often flexible and can be easily folded, twisted, or shaped, allowing for various applications.

2. Lightweight: Nonwoven fabrics are typically lightweight, which makes them easy to carry and use.

3. Breathability: Many nonwoven fabrics allow air and moisture to pass through, providing a comfortable wearing experience.

4. Waterproofness: Some nonwoven fabrics possess waterproof properties, making them suitable for the production of water-resistant products.

5. Durability: Nonwoven fabrics are generally durable and resistant to wear and tear, making them suitable for the production of long-lasting products.

6. Easy Production: Nonwoven fabrics can be produced more quickly and cost-effectively compared to traditional weaving or knitting processes.

7. Variety: Nonwoven fabrics can have various properties depending on the type of fibers used and the production method employed. This versatility allows for their use in a wide range of applications.

Nonwoven fabrics find extensive use in industries such as hygiene products, medical materials, home textiles, automotive industry, and agriculture. Their flexibility, durability, and versatility make nonwoven fabrics a widely preferred textile material.

Certifications hold significant importance in the field of medical textiles due to the direct association of these products with human health. Here are some reasons why certifications are crucial in the medical textile field:

1. Quality Assurance: Quality is paramount in medical textile products. Certified products demonstrate adherence to specific standards, providing assurance of quality and reliability. This enhances the trustworthiness and effectiveness of the products.

2. Product Safety: Certified medical textile products are deemed safer and less risky for users. These products undergo specific tests to mitigate health risks and are manufactured in compliance with certain requirements, ensuring user safety.

3. Patient and Staff Safety: Ensuring the safety of patients and healthcare workers is paramount in the medical textile field. Certified products help reduce the risk of infections and ensure the safety of users.

4. Compliance with Regulations: Certifications related to medical textile products demonstrate compliance with local and international regulations. This proves that the products meet legal requirements, ensuring legal safety.

5. Market Access: Certified medical textile products are more readily accepted in the market and appeal to a broader customer base. Holding a certification provides customers with assurance regarding the quality and reliability of the products.

In conclusion, certifications play a vital role in ensuring product quality, safety, and compliance with regulations in the medical textile field. They enhance both manufacturer and user confidence and contribute to maintaining industry standards.

Technical textile fabrics are specialized materials designed for industrial or technical purposes, offering unique properties for various applications. These fabrics have a wide range of uses across different industries. Here are some common applications of technical textile fabrics:

1. Automotive Industry: Technical textile fabrics are used in automotive upholstery, seat covers, airbags, sound insulation, and fire resistance.

2. Construction and Building Materials: High-strength technical textile fabrics are used in construction for roofing membranes, wall coverings, insulation materials, and concrete reinforcement.

3. Defense and Military Applications: Technical textile fabrics are used in military equipment, uniforms, ballistic fabrics, and armor materials.

4. Aviation Industry: Technical textile fabrics are utilized in aircraft interiors for upholstery, insulation panels, high-strength ropes, and parachutes.

5. Sports and Outdoor Apparel: Technical textile fabrics are used in sportswear and outdoor gear for waterproofing, breathability, and flexibility.

6. Medical Textiles: Medical garments, surgical gowns, patient attire, and bandages are made using technical textile fabrics.

7. Filtration and Cleaning Materials: Technical textile fabrics are used in ventilation systems, water treatment facilities, and industrial filters.

8. Electronics and Technology: Technical textile products such as insulation materials and electromagnetic shields are used to protect electronic devices.

These applications represent just a few examples of where technical textile fabrics are commonly used, but they extend to various other industries as well. Technical textiles play a crucial role in many sectors and continue to be the subject of ongoing research for new and innovative applications.

Medical apparel plays a critical role in ensuring the safety, comfort, and hygiene of healthcare professionals and patients. Here are some reasons why medical apparel is important:

1. Infection Control: Medical apparel helps prevent the spread of infections. Especially in hospital and clinic settings, proper attire contributes to maintaining hygienic standards and reducing the risk of infection.

2. Patient Protection: The use of appropriate medical apparel by healthcare personnel protects patients from bacteria, viruses, and other infections. This reduces the risk of patients acquiring infections while receiving healthcare services.

3. Protection for Healthcare Workers: Medical apparel protects healthcare workers from various hazards. Particularly during surgical procedures, garments like surgical gowns reduce the risk of skin contact and potential hazards from blood and other bodily fluids.

4. Preservation of Sterile Environments: Medical apparel aids in the preservation of sterile environments. In surgical areas and other sensitive medical environments, the use of proper medical attire can impact the sterility of the environment and surgical outcomes.

5. Professionalism and Trust: The use of medical apparel by healthcare professionals enhances patient trust and creates a professional image. This helps patients feel safe during their treatment processes, knowing they are receiving reliable healthcare services.

In conclusion, medical apparel is of vital importance in ensuring safety, maintaining hygienic standards, and providing quality patient care in healthcare settings. Therefore, healthcare institutions should implement appropriate medical apparel policies and take necessary measures to ensure the safety of both staff and patients.

Scrubs uniforms are specialized garments worn by healthcare professionals in various healthcare settings. Here are the applications of scrubs uniforms:

1. Hospitals: Scrubs uniforms are commonly worn by doctors, nurses, surgeons, and other healthcare staff in hospitals. In this environment, it is important for the uniforms to be comfortable, provide freedom of movement, and be hygienic.

2. Clinics: Scrubs uniforms are also widely used in doctor's offices and other medical clinics. In these settings, the uniforms enable healthcare professionals to work comfortably and maintain a hygienic environment.

3. Operating Rooms: During surgical procedures, surgeons, surgical technicians, and other members of the surgical team wear scrubs uniforms. These uniforms are specially designed to maintain the sterility of the surgical area.

4. Emergency Departments: Healthcare staff working in emergency departments also wear scrubs uniforms. In this environment, it is important for the uniforms to be durable and easily cleanable and disinfectable.

5. Other Healthcare Facilities: Personnel working in rehabilitation centers, nursing homes, and other healthcare facilities may also wear scrubs uniforms. These uniforms contribute to the comfort and hygiene of healthcare delivery.

Scrubs uniforms play an important role in the functionality and comfort of healthcare professionals and have a wide range of applications in various healthcare settings.

Patient gowns should be designed with specific features to ensure patient comfort, maintain a hygienic environment, and enhance the safety of healthcare workers. Here are the key features that patient gowns should have:

1. Comfort: Patient gowns should be designed to ensure patient comfort. They should be made from lightweight and breathable materials that do not cause irritation to the skin.

2. Ease of Donning: Patient gowns should be designed for easy donning and removal. Particularly for patients with limited mobility, they should be easy to put on and take off.

3. Adjustability: Patient gowns should be adjustable to accommodate different body sizes and shapes. Adjustable straps or ties can help the gown fit the patient's body better.

4. Durability: Patient gowns should be made from durable materials that can withstand frequent washing and disinfection. Additionally, gowns should be able to withstand long-term use.

5. Hygiene: Patient gowns should be made from hygienic materials to reduce the risk of infection. They should be regularly cleaned and disinfected to maintain cleanliness.

6. Functionality: Patient gowns should be practical and functional to meet the needs of patients. For example, pockets or additional accessories can be useful for carrying personal items or meeting other needs.

7. Affordability: Patient gowns should be affordable for hospitals or healthcare facilities. Affordable gowns can fit within the budget constraints of healthcare providers.

Ensuring that patient gowns have these features can improve patient satisfaction and safety, as well as the efficiency of healthcare delivery. Therefore, these factors should be considered when selecting patient gowns.

Cleaning a patient gown is crucial for maintaining a hygienic environment and reducing the risk of infection. Here are the steps for cleaning a patient gown:

1. Prompt Action: After removing a soiled patient gown, begin the washing process as soon as possible. Keep the soiled gown in a ventilated area and avoid direct contact.

2. Pre-wash: Pre-wash the soiled gown with a solution containing water and detergent. This helps dissolve and loosen organic matter from the gown.

3. Machine Washing: Wash the gown in an appropriate washing machine. Pay attention to the instructions on the label before washing and use the appropriate temperature setting.

4. Drying: Dry the washed patient gown by hanging it in the air or using a dryer. If using a dryer, dry at an appropriate temperature.

5. Ironing (Optional): If needed, iron the gown at an appropriate temperature. This ensures the gown looks neat and creates a sterile environment.

6. Storage: Store the cleaned and dried patient gown in a clean and dry area. The patient gown should be readily accessible for reuse when needed.

Regularly cleaning and disinfecting patient gowns is an important way to reduce the risk of infection and maintain a hygienic environment. By following the above steps, you can ensure that a patient gown is effectively cleaned.

A surgical gown is an essential protective garment used in surgical procedures, and it's crucial to use it correctly. Here are the steps for properly using a surgical gown:

1. Clean Hands: Before putting on the surgical gown, thoroughly wash and disinfect your hands. Clean hands are important to maintain the sterility of the surgical area.

2. Proper Donning: Before donning the surgical gown, carefully open it with clean, dry hands, and slip your arms into the gown sleeves. Pull the front of the gown forward, holding it in front of your body, and pull it back smoothly into place.

3. Fastening: Use the ties or clips at the back of the gown to secure it snugly around your body. The fastening should be secure but comfortable.

4. Keeping Closed: During the surgery, keep the gown closed and ensure it does not open during critical surgical steps. Use appropriate surgical gloves if necessary to provide additional protection.

5. Changing: The gown should be changed immediately if it becomes soiled or torn. During surgical procedures, you may need to change the gown; in such cases, carefully remove the soiled gown and put on a clean one.

6. Safe Disposal: Used gowns should be disposed of in appropriate containers where medical waste is safely disposed of.

When used correctly, a surgical gown helps ensure the safety of the surgical team and the patient and reduces the risk of infection. Therefore, it's important to use the gown properly during surgical procedures.

1. Contrast Reduction: Green is the opposite color of red, and it is believed that the red blood used in surgery can cause eye strain and fatigue. Green surgical attire rests the eyes and reduces contrast in the surgical field, potentially helping surgeons to focus for longer periods.

2. Symbolizing Sterility: Green is associated with freshness and health in nature. Therefore, green surgical attire may help create an impression of sterility and cleanliness.

3. Minimizing Eye Fatigue: Green is a color found in natural environments and is known to provide rest for the eyes. In the intense work environments where surgeons need to focus for extended periods, wearing green may help reduce eye fatigue.

4. Practicality: Green surgical attire can hide stains and blood, making it easier for surgeons to overlook contamination on their clothing.

However, in modern times, surgeons wear a variety of colors beyond traditional green, and the choice of color for surgical attire may depend on the preferences of the hospital or surgical team. Therefore, while there is no definitive answer to why surgeons wear green, the above theories are commonly accepted explanations.

The cleanliness of medical garments is crucial for maintaining a hygienic environment and reducing the risk of infection. Cleaning medical garments should be done following these steps:

Pre-treatment: Soiled garments should first be removed from the worn areas and placed outside contaminated zones. Hands, gloves, and other protective equipment should be properly removed and discarded.

Pre-wash: Soiled garments should be pre-washed with a solution containing water and detergent. This helps dissolve and remove organic matter from the garments.

Washing: Garments should be washed with an appropriate detergent and at the specified temperature. Hot water helps to kill bacteria and other microorganisms.

Rinsing: Washed garments should be rinsed with clean water. This ensures that detergent residues and dirt are completely removed.

Disinfection: Garments should be disinfected with an appropriate disinfectant solution. This kills potential pathogens on the garments and reduces the risk of infection.

Drying: Garments should be dried either in a dryer or naturally in the sun. High temperatures help to remove moisture from the garments and kill bacteria.

Ironing: When necessary, garments should be ironed at an appropriate temperature. This helps garments to be properly folded and hygienically stored.

In conclusion, the cleaning of medical garments should be done carefully, following proper hygiene standards. These steps enhance infection control and ensure the safety of healthcare providers and patients.

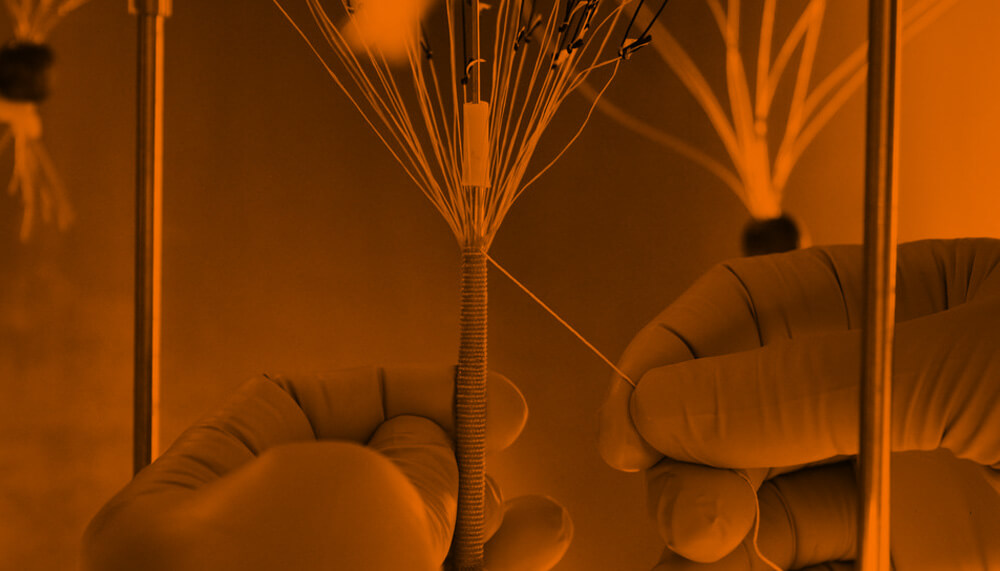

The fabric selection for medical garments should be carefully considered based on the intended use, functional requirements, and comfort. Medical garments typically require properties such as hygiene, durability, mobility, and fluid resistance. Here are some factors to consider when determining suitable fabrics for medical garments:

Hygiene: It's important for medical garments to be hygienic, so fabrics that are easily cleaned and disinfected should be preferred.

Durability: Garments worn in hospital environments are frequently laundered and disinfected, so they should be made from durable fabrics that can withstand repeated washing and maintain their integrity over time.

Mobility: Medical personnel need to move comfortably, so fabrics that are flexible and elastic should be chosen to prevent restrictions during daily activities and ensure ease of movement.

Fluid Resistance: Medical garments, especially for those working in surgical areas, should be fluid-resistant or waterproof to prevent the passage of fluids onto the skin or undergarments.

Breathability: Garments should be breathable to keep medical personnel comfortable and cool. Fabrics that allow airflow and reduce sweating should be selected.

Allergic Reactions: Fabrics that may cause allergic reactions in medical personnel should be avoided. Therefore, hypoallergenic and skin-friendly fabrics should be preferred.

In conclusion, the fabric selection for medical garments should take into account the usage area and requirements. Factors such as hygiene, durability, mobility, fluid resistance, breathability, and allergic reactions play a significant role in determining the appropriate fabric.